Products

Products

Single-layer board

A single-layer board is the most basic PCB and can only carry fewer components and simpler circuit designs.

Double layer board

A double-layer PCB refers to a PCB with two conductive layers. Compared to a single-layer PCB, a double-layer PCB can support more components and more complex circuits.

Multi-layer board

Multi-layer boards have more layers, support more complex circuit designs, and can achieve high-density and miniaturized designs.

Product Overview

Product Overview

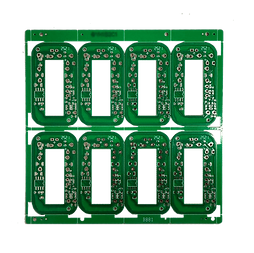

Single-layer board

Single-layer boards are the most basic printed circuit boards. All circuit components are arranged on one side of the board, and the other side usually does not carry any circuits. Due to their simple structure and low cost, single-layer boards are widely used in simple electronic products.

Technical Specifications

-

Materials: FR4, CEM1, CEM3

-

Copper thickness: o.5~3oz up

-

Surface treatment: HASL, immersion gold, OSP

-

Size range: Customizable according to requirements, standard sizes available

-

Minimum line width/spacing:4/4mil

Application areas

Home appliances , low-cost electronics , toys and consumer products

Manufacturing Capabilities

Manufacturing Capabilities

We rely on advanced technology and highly qualified employees to ensure that each stage of production meets high standards. Whether it is single-layer, double-layer or multi-layer PCB, we can handle it efficiently and provide fast delivery services. We also provide customized production solutions according to customer needs.

Through continuous technological innovation and equipment upgrades, we stay ahead in the field of PCB manufacturing and provide stable and reliable solutions for industries such as electronics, communications, automotive and medical.

Our Service

Our Services

We provide a full range of services to ensure that each product can meet the needs of customers and provide the best user experience.

PCB layout design

Provide schematic design, PCB layout, high-frequency design, etc. to ensure functionality and reliability.

PCB printing manufacturing

Provide professional technical support and answers to problems encountered by customers during the design and manufacturing process.

Multiple material selection

Choose the right substrate based on your needs to ensure PCB performance, durability and reliability.

SMT assembly service

Provides automated and manual soldering to ensure efficient assembly and precise component installation.

Product quality testing

Conduct electrical tests, functional tests and X-ray inspections to ensure high-quality products.